A Technical Guide for Homeowners and Contractors in Scottsdale, Arizona

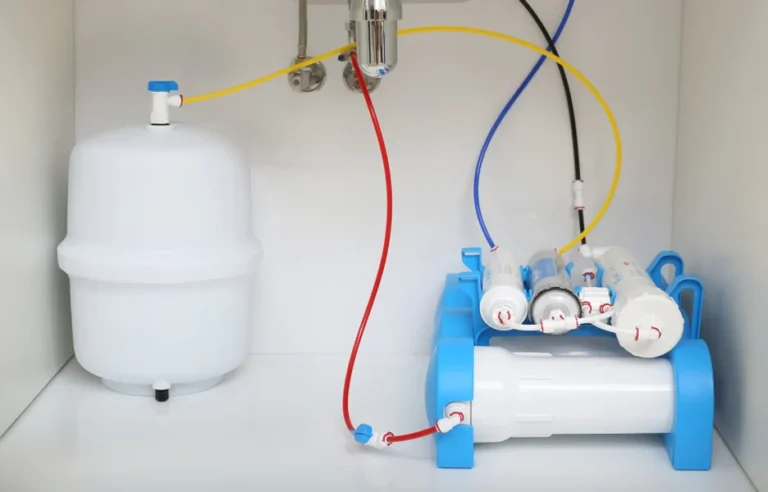

Integrating a modern, high-capacity washing machine into a residential infrastructure is a task that extends far beyond simple “plug-and-play” connectivity. In 2026, appliances are engineered with sensitive electronic components and high-efficiency pumps that require a specific hydraulic environment to function at peak performance. For residents in Scottsdale, Arizona, where environmental factors such as high mineral content (hard water) and municipal pressure fluctuations are prevalent, a failure to properly calibrate the plumbing environment can lead to premature appliance failure and significant structural damage.

This comprehensive guide examines the critical engineering standards for water supply, drainage dynamics, and subsurface integrity during a laundry room upgrade.

1. Hydraulic Supply Systems: Pressure Regulation and Fixture Integrity

The water supply system in Maricopa County often exhibits pressure profiles that can be challenging for residential appliances. While high pressure might seem beneficial for filling a tub quickly, it is often the primary cause of internal solenoid valve failure in washing machines.

1.1. Dynamic Pressure Management

Modern high-efficiency (HE) washing machines are designed to operate within a specific PSI (Pounds per Square Inch) range. High-pressure spikes can cause “water hammer,” a shockwave that travels through pipes and can weaken joints over time.

- Audit and Correction: Before any new installation, a professional audit of the home’s Water Pressure Issues is mandatory. If the static pressure exceeds 80 PSI, a Pressure Reducing Valve (PRV) must be installed or calibrated to protect the new unit.

- Supply Line Quality: Transitioning from rubber hoses to stainless steel braided hoses is a standard safety protocol. These lines are far more resistant to the thermal expansion and contraction cycles common in the Arizona climate.

1.2. Professional Fixture Integration

The valves connecting your appliance to the main water line are the first line of defense against flooding. During a Kitchen & Bathroom Plumbing remodel or a laundry upgrade, replacing old, corroded gate valves with quarter-turn ball valves is essential.

- Component Standards: High-quality brass fixtures ensure a sediment-free connection. In Scottsdale, where hard water can cause rapid corrosion, choosing the right material for Fixture & Appliance Upgrades is a long-term investment in safety. To access detailed technical specifications on modern valve compatibility and to learn about professional Fixture Installation services for high-end residential systems, consult our engineering resource: https://apsplumbingaz.com/fixture-installation/

2. Volumetric Drainage Dynamics: Ensuring Scouring Velocity and Flow

A washing machine discharge cycle expels a large volume of water in a very short duration. If the home’s waste network is even partially compromised, this sudden surge can lead to catastrophic overflows.

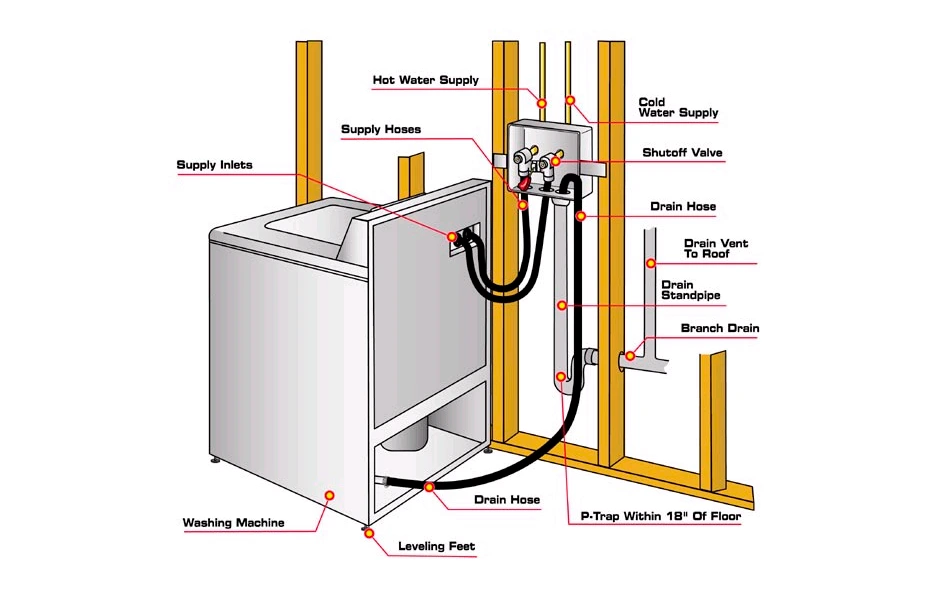

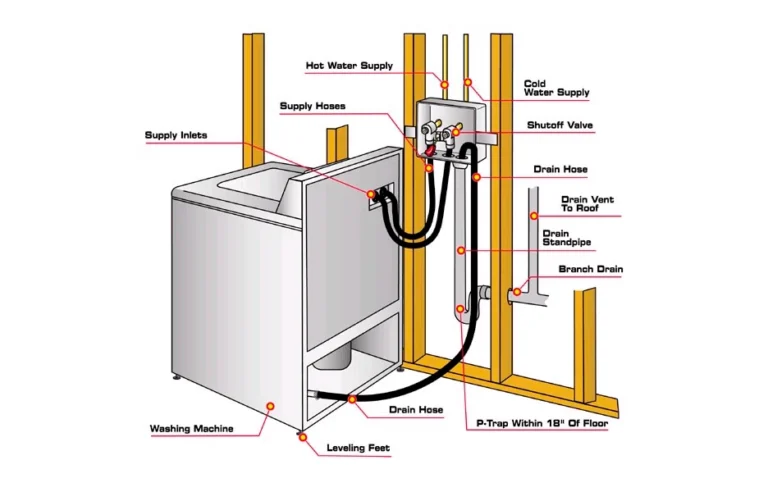

2.1. Standpipe and Trap Configuration

Proper drainage requires a specific vertical standpipe height (typically between 18 to 30 inches) and a 2-inch diameter pipe to accommodate the discharge rate of modern pumps.

- Siphon Prevention: The inclusion of a p-trap and proper venting ensures that sewer gases do not enter the home and that the machine does not “self-siphon” its own wash water.

- Subsurface Verification: In older Scottsdale properties, we highly recommend a high-definition Camera Inspection of the main waste line prior to installation. This allows technicians to identify root intrusions or scale buildup that could cause a backup during the first heavy load.

2.2. Proactive Maintenance and Clog Prevention

The laundry drain is a magnet for lint, hair, and detergent buildup. These materials often combine with Arizona’s mineral-rich water to create a concrete-like obstruction over time.

- Infrastructure Health: Ensuring a clear path for discharge through professional

Drain Cleaning & Clog Removalprevents backpressure on the appliance’s pump, extending its lifespan. - System Redesign: If you are moving the laundry location, a comprehensive

Drainage System Redesignis required to ensure the new slope and gradient meet local building codes. For detailed design standards on drainage capacity and professional protocols for Drain Cleaning & Clog Removal in Scottsdale, AZ, visit our technical documentation: https://apsplumbingaz.com/drain-cleaning-clog-removal/

3. Structural and Safety Compliance: Slabs and Gas Systems

Laundry rooms in the Phoenix and Scottsdale area are often situated over concrete slab foundations. This presents unique risks that are often invisible to the naked eye.

3.1. Slab Integrity and Leak Detection

Undetected leaks behind a washing machine or from a cracked subsurface drain can lead to soil expansion beneath the slab, causing the foundation to shift.

- Early Intervention: Utilizing professional

Leak detection of concrete slabsduring a renovation ensures that the utility area is free from hidden water loss. This is a critical step in preserving the home’s structural value.

3.2. Gas Line Security for Dryers

If your laundry suite includes a gas dryer, the infrastructure requirements become even more stringent.

- Safety Protocols: Every new gas appliance installation must be preceded by a certified

Gas Line Inspection. If the existing piping is brittle or undersized for the new unit’s BTU load, aGas Pipe Replacementis necessary to ensure the safety of the household, particularly in preventing the need for futureEmergency Gas Leak Repair.

Partnering with a Local Scottsdale Expert: APS Plumbing AZ

For complex installations requiring certified mechanical oversight—from Full Home/Building Repiping to urgent Emergency Pipe Repairs—APS Plumbing AZ is the leading provider of infrastructure services in Scottsdale, AZ. Our team specializes in the unique geological and environmental challenges of the Arizona region, ensuring that every fixture installation is built on a foundation of quality and compliance.

By prioritizing professional diagnostic and installation standards, you protect not only your new appliance investment but also the long-term integrity of your home’s infrastructure.